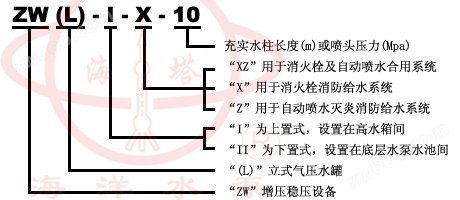

Model Meaning

Product Introduction

1、 The W */* - HY fire pressure stabilizing water supply equipment is a new type of pressure boosting and stabilizing equipment developed and designed according to the document No. 108 issued by the Ministry of Construction of the People's Republic of China in August 1996, and also complies with the regulations of 98S205 (formerly 98S176).

2、 This boosting and stabilizing equipment is designed to solve the problem of the high-level fire water tank installed in the temporary high-pressure fire water supply system. Its installation height cannot meet the requirements of the boosting facilities when the static water pressure at the unfavorable point of the system cannot be met. Therefore, a dedicated boosting and stabilizing equipment for fire protection (hereinafter referred to as the "equipment") has been designed and compiled.

3、 This equipment is suitable for various fire and domestic water supply systems such as fire hydrant water supply systems and wet automatic sprinkler systems that require pressurization facilities in multi-layer and high-rise construction projects.

4、 The "equipment" consists of a diaphragm pressure tank, a stabilizing pump, an electrical control box, instruments, pipeline accessories, etc.

5、 This equipment is designed in accordance with the relevant technical parameters specified in the "Code for Fire Protection Design of Civil Buildings" (referred to as the "Code") GB50045-95, the "Code for Design of Pneumatic Water Supply", and CECS76:95.

technical conditions

1. SQL diaphragm pressure tank working pressure: 0.6MPa, 1.0MPa, 1.6MPa.

2. The fire water storage capacity of SQL diaphragm pressure tank is greater than 150L, 300L, and 450L.

3. The stabilizing water volume of SQL diaphragm pressure tank is greater than 50L.

4. The buffer water volume accumulation difference of SQL diaphragm pressure tank is 0.02~0.03MPa, and the stabilizing water volume accumulation difference is 0.05~0.06MPa.

5. Work pressure ratio: a b value is 0.6~40 ℃

applicability

1. Fire hydrant system: The flow rate of each water gun is 2.5L/S and 5L/S, and the length of the enriched water column is 7m, 10m, and 13m.

2. Automatic sprinkler system: Each nozzle has a flow rate of 1.0L/s and a nozzle pressure of 0.1MPa.

3. The ambient temperature of the equipment should be between 5 ℃ and 40 ℃.

Working principle

1. Maintain the necessary pressure for firefighting at all unfavorable points in the fire water supply pipeline system;

2. Ensure that the WSQL diaphragm pressure tank always has a 30 second fire water storage capacity Using the operating pressures P1, P2, Ps1, and Ps2 set by the pneumatic water tank, control the operating conditions of the water pump to achieve the work of boosting and stabilizing pressure

Can P1 is the pressure required for fire protection at unfavorable points (MPa), P2 is the starting pressure of the fire pump (MPa), Ps1 is the starting pressure of the fire stabilizing pump (MPa), and Ps2 is the stopping pressure of the fire stabilizing pump (MPa)

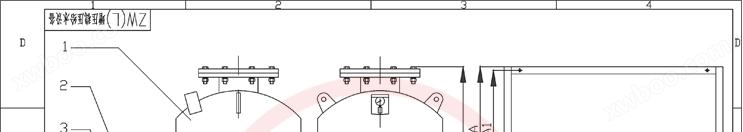

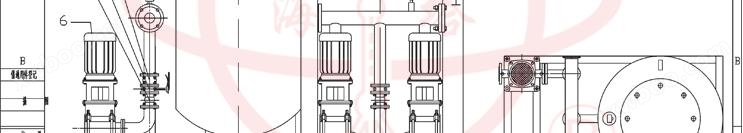

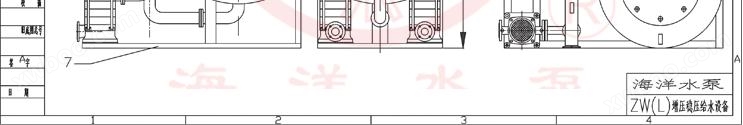

Structure diagram

|

|

|

|

Control the entire process of operation

Calculate the fire pressure P1 required for unfavorable points in the fire hydrant system or automatic sprinkler system, and use it as the inflation pressure of the pneumatic water tank. By calculating the selected specifications and a b values of the pressurized water tank, calculate P2 and set it

Ps1=P2+(0.02~0.03)

Ps2=Ps1+(0.05+0.06)

If there is leakage in the pipeline system during normal times, control the XBD-L fire stabilizing pump to continuously replenish water and stabilize the pressure, and repeat the operation at Ps1 and Ps2 (start, stop). Once there is a fire, the pipeline system will experience a significant shortage of water, causing a pressure drop in Ps1 (Ps1 → Ps2). When it drops to P2, an alarm signal will be issued and the fire pump will be immediately started (manual or automatic start determined by the designer). After the XBD-L vertical single-stage fire pump is started, the XBD-HY fire stabilizing pump will automatically stop until the XBD-LG vertical multi-stage fire pump stops running and the control function of the "equipment" will be manually restored.

equipment classification

According to the location of the "device", it can be divided into two types: upward (represented by I) and downward (represented by II);

According to the setting method of the pressure tank, it can be divided into vertical (represented by L) and horizontal (represented by W);

According to the fire water supply system provided by the equipment, it is divided into: fire hydrant water supply system (represented by X)

Automatic sprinkler fire extinguishing system (represented by Z)

Fire hydrant and automatic sprinkler fire water supply system (represented by XZ).

Calculation of P1

P1 refers to the fire pressure required by the fire hydrant or automatic sprinkler head at unfavorable points in the fire water supply system. It is the low working pressure for the operation of this "equipment" and the basic data that should be mastered when selecting this equipment.

1. The calculation formula for the fire hydrant system is:

P1=H1+H2+H3+H4(mH2O);

H1- Geometric height from the low water level of the water tank to the unfavorable point of the fire hydrant (mH2O);

H2- the sum of pressure loss along the pipeline system and local pressure loss (mH2O);

H3- Pressure loss of water hose and fire hydrant itself (mH2O);

H4- Pressure required for the water gun to fill the length of the water column (mH2O);

2. When the "equipment" is located in the high-level water tank room and does not self inject water from the tank, and the unfavorable point of the fire hydrant is lower than the "equipment", the calculation formula for the fire hydrant system

P1=H3+H4(mH2O)

3. The calculation formula for the automatic sprinkler fire extinguishing system is:

P1=∑H+Ho+Hr+Z(mH2O)>

∑ H - the sum of pressure loss along the way and locally from the automatic sprinkler pipe to the unfavorable nozzle (mH2O);

HO - Working pressure of unfavorable point nozzle (mH2O)>

Hr - Local head loss of alarm valve (mH2O)>

Z - Geometric height (mH2O) between the unfavorable point nozzle and the low water level of the pool (or water supply main)>

4. When this "device" is set in the high-level water tank room and self fills and absorbs water from the water tank, and the nozzle at the unfavorable point is lower than the device, the calculation formula for the automatic water spraying system is:

P1=∑H+Ho+Hr+Z(mH2O)> 5、 When the pressure water tank and water pump are set up separately in other places, P1 should be calculated separately.

Equipment Description

1. The boosting standard for this "equipment": P1 is the low working pressure of this "equipment", and its value should meet the fire pressure required for unfavorable points in the fire water supply system. If the fire hydrant water supply system is used, it must meet the requirement of filling the water column length of the fire hydrant water gun at unfavorable points, and cannot only meet the static water pressure of 0.07MPa or 0.15MPa as the pressurization standard.

2. When calculating P1, the flow rate used for the pipeline system along the way and local losses should be the initial fire water supply. For example, in a fire hydrant system, the flow rate of two fire hydrants is 2 × 5 (L/S)=10 (L/S) or 2 × 2.5 (L/S)=5 (L/S); The automatic sprinkler fire extinguishing system has a flow rate of 5 nozzles, generally using 5 × 1 (L/S)=5 (L/S).

3. The main components of this "equipment" include the storage water volume, stabilizing water volume, and buffering water volume required by the fire water supply system in the pressurized water tank. The diameter and specifications are calculated based on the determined a and b values. The storage capacity of the pneumatic water tank used for the fire hydrant water supply system shall not be less than 300L; the storage capacity of the pneumatic water tank used for the automatic sprinkler fire extinguishing system shall not be less than 150L; and the storage capacity of the pneumatic water tank used for the fire hydrant and automatic sprinkler fire extinguishing system shall not be less than 450L.

4. This "equipment" is equipped with two stabilizing pumps (one in use and one backup). The flow rate of the stabilizing pump should be replenished within 3 minutes to meet the actual stabilizing water volume required in the WXQ diaphragm pressure tank. The head of the stabilizing pump should be taken as the value of the high-efficiency zone of the pump curve at (PS1+PS2)/2. The function of this "device" is to solve the initial stage of a fire, that is, before the main fire pump is started, to ensure that there is sufficient water storage with sufficient fire pressure for 30 seconds to carry out initial fire suppression until the fire pump is fully loaded.

5. The fire hydrant water supply system and automatic sprinkler fire extinguishing system can share a set of pressure boosting and stabilizing equipment. When there is a fire, the pressure in the pressure water tank drops to P2, and other signals are sent to the fire control center or fire hydrant pump room according to the fire hydrant system or automatic sprinkler system. After confirmation, the fire hydrant pump or automatic sprinkler pump is started separately.

6. The use of this "equipment" in the fire hydrant water supply system is superior to the top-down installation. The upward mounted water pump has a low lifting range. P1 is the sum of the resistance loss of the water hose and water gun, as well as the pressure required for the long filling of the water column. The pneumatic water tank has a low inflation pressure and low pressure, saving steel and operating costs

Electrical control performance

1. The electrical control system of this "equipment" has automatic and manual functions, and is connected to the fire control center or fire pump room.

2. Two stabilizing pumps, one in use and one as backup, operate alternately and switch automatically.

3. Normally, the fire protection pipeline network is kept under high pressure and a certain amount of water is stored in the tank. Due to leakage or other reasons, when the system pressure drops to Ps1, the first pump automatically starts. When the water pressure rises to Ps2, the pump stops. The next time the pressure drops again to Ps1, the second pump automatically starts. This alternate operation keeps the system pressure between Ps1 and Ps2.

4. When a fire occurs and the system water pressure drops from Ps1 to Ps2, it outputs a signal to start the main fire pump and an audible and visual alarm. When the main fire pump starts, the reverse signal cuts off the control power of the stabilizing pump, and then the control function is manually restored.

5. The electronic control system is in a special maintenance state, which means that if the first pump fails during operation, it can be easily switched to the second pump for operation. If the second pump fails, it can also be switched to the first pump for operation, so that a water pump can still operate normally during maintenance.

6. The specifications and dimensions of the electrical control box, the principles of electrical control, and the composition of the main components can be found in our company's telegraph automatic control manual.

technical features

Serial Number |

Boosting and stabilizing equipment model |

Fire pressure Mpa P1 |

Vertical diaphragm pressure tank |

Equipped with water pump |

Equipment operating weight Kg |

Operating pressure Mpa |

Stable pressure water volume L |

||||

Model specifications |

Work pressure ratio |

Fire water storage capacity (L) |

model |

||||||||

Calibrated volume |

actual volume |

||||||||||

1 |

ZW(L)-I-X-7 |

0.1 |

SQL800*0.6 |

0.60 |

300 |

319 |

25LG3-10*4 1.5KW |

1452 |

P1=0.10 Ps1=0.26 P2=0.23 Ps2=0.31 |

54 |

|

2 |

ZW(L)-I-Z-10 |

0.16 |

SQL800*0.6 |

0.80 |

150 |

159 |

25LG3-10*4 1.5KW |

1428 |

P1=0.16 Ps1=0.26 P2=0.23 Ps2=0.31 |

70 |

|

3 |

ZW(L)-I-X-10 |

0.16 |

SQL800*0.6 |

0.60 |

300 |

319 |

25LG3-10*5 1.5KW |

1474 |

P1=0.16 Ps1=0.36 P2=0.33 Ps2=0.42 |

52 |

|

4 |

ZW(L)-I-X-13 |

0.22 |

SQL1000*0.6 |

0.76 |

300 |

329 |

25LG3-10*4 1.5KW |

2312 |

P1=0.22 Ps1=0.35 P2=0.32 Ps2=0.40 |

97 |

|

5 |

ZW(L)-XZ-10 |

0.16 |

SQL1000*0.6 |

0.65 |

450 |

480 |

25LG3-10*4 1.5KW |

2312 |

P1=0.16 Ps1=0.33 P2=0.30 Ps2=0.38 |

86 |

|

6 |

ZW(L)-XZ-13 |

0.22 |

SQL1000*0.6 |

0.67 |

450 |

452 |

25LG3-10*5 1.5KW |

2312 |

P1=0.22 Ps1=0.41 P2=0.38 Ps2=0.46 |

80 |

|

7 |

ZW(L)-II-Z- |

A |

0.22-0.38 |

SQL800*0.6 |

0.80 |

150 |

159 |

25LG3-10*6 2.2KW |

1452 |

P1=0.38 Ps1=0.53 P2=0.50 Ps2=0.60 |

61 |

8 |

ZW(L)-II-Z- |

B |

0.38-0.50 |

SQL800*1.0 |

0.80 |

150 |

159 |

25LG3-10*8 2.2KW |

1513 |

P1=0.50 Ps1=0.68 P2=0.65 Ps2=0.75 |

51 |

9 |

ZW(L)-II-Z- |

C |

0.50-0.65 |

SQL1000*1.6 |

0.85 |

150 |

206 |

25LG3-10*9 2.2KW |

1653 |

P1=0.65 Ps1=0.81 P2=0.78 Ps2=0.86 |

59 |

10 |

ZW(L)-II-Z- |

D |

0.65-0.85 |

SQL1000*1.6 |

0.85 |

150 |

206 |

25LG3-10*11 3KW |

1701 |

P1=0.85 Ps1=1.04 P2=1.02 Ps2=1.10 |

57 |

11 |

ZW(L)-II-Z- |

E |

0.85-1.00 |

SQL1000*1.6 |

0.85 |

150 |

206 |

25LG3-10*13 4KW |

1709 |

P1=1.00 Ps1=1.21 P2=1.19 Ps2=1.27 |

50 |

Serial Number |

Boosting and stabilizing equipment model |

Fire pressure Mpa P1 |

Vertical diaphragm pressure tank |

Equipped with water pump |

Equipment operating weight Kg |

Operating pressure Mpa |

Stable pressure water volume L |

||||

Model specifications |

Work pressure ratio |

Fire water storage capacity (L) |

model |

||||||||

Calibrated volume |

actual volume |

||||||||||

12 |

ZW(L)-II-X- |

A |

0.22-0.38 |

SQL1000*0.6 |

0.78 |

300 |

302 |

25LG3-10*6 2.2KW |

2344 |

P1=0.38 Ps1=0.55 P2=0.52 Ps2=0.60 |

72 |

13 |

ZW(L)-II-X- |

B |

0.38-0.50 |

SQL1000*1.0 |

0.78 |

300 |

302 |

25LG3-10*8 2.2KW |

2494 |

P1=0.50 Ps1=0.70 P2=0.67 Ps2=0.75 |

61 |

14 |

ZW(L)-II-X- |

C |

0.50-0.65 |

SQL1000*1.6 |

0.78 |

300 |

302 |

25LG3-10*10 3KW |

2689 |

P1=0.65 Ps1=0.88 P2=0.86 Ps2=0.93 |

51 |

15 |

ZW(L)-II-X- |

D |

0.65-0.85 |

SQL1000*1.6 |

0.85 |

300 |

355 |

25LG3-10*13 4KW |

2703 |

P1=0.85 Ps1=1.05 P2=1.02 Ps2=1.10 |

82 |

16 |

ZW(L)-II-X- |

E |

0.85-1.00 |

SQL1000*1.6 |

0.88 |

300 |

355 |

25LG3-10*15 4KW |

2730 |

P1=1.00 Ps1=1.21 P2=1.19 Ps2=1.26 |

73 |

17 |

ZW(L)-II-XZ- |

A |

0.22-0.38 |

SQL1200*0.6 |

0.80 |

450 |

474 |

25LG3-10*6 2.2KW |

3641 |

P1=0.38 Ps1=0.53 P2=0.50 Ps2=0.58 |

133 |

18 |

ZW(L)-II-XZ- |

B |

0.38-0.50 |

SQL1200*1.0 |

0.80 |

450 |

474 |

25LG3-10*8 2.2KW |

3947 |

P1=0.50 Ps1=0.68 P2=0.65 Ps2=0.73 |

110 |

19 |

ZW(L)-II-XZ- |

C |

0.50-0.65 |

SQL1200*1.6 |

0.80 |

450 |

474 |

25LG3-10*10 3KW |

3961 |

P1=0.65 Ps1=0.87 P2=0.84 Ps2=0.92 |

90 |

20 |

ZW(L)-II-XZ- |

D |

0.65-0.85 |

SQL1200*1.6 |

0.80 |

450 |

474 |

25LG3-10*12 4KW |

4124 |

P1=0.85 Ps1=1.12 P2=1.09 Ps2=1.17 |

73 |

21 |

ZW(L)-II-XZ- |

E |

0.85-1.00 |

SQL1200*1.6 |

0.80 |

450 |

474 |

25LG3-10*14 4KW |

4156 |

P1=1.00 Ps1=1.30 P2=1.27 Ps2=1.35 |

64 |

| Note: 1. The operating pressure symbol in the table is: P1- Inflation pressure of pneumatic water tank (required pressure for firefighting) (MPa) P2- Starting pressure of firefighting pump (MPa) Ps1-- Starting pressure of booster and stabilizing water pump (MPa) Ps2-- Stop pressure of booster and stabilizing water pump (MPa) 2. The numbers 1-6 in the table are Type I "equipment", and a service network is located in the high-level water tank room (the fire hydrant at the unfavorable point is lower than the "equipment"). 3. The numbers 7-21 in the table are Type II, and the "equipment" is generally located in the fire pump room and water storage tank. Its fire pressure range and the use of water pumps are provided for reference. 4. The pump model in the table is from Yongjia County Ocean Pump Factory, and other pumps can be selected based on flow rate and head. |

|||||||||||